CONTRACT

MANUFACTURING

WHAT IS PHARMACEUTICAL CONTRACT MANUFACTURING?

The process of producing pharmaceutical medications or nutritional supplements under contract is known as pharmaceutical contract manufacturing.

Put another way, a pharmaceutical firm contracts with a manufacturing company to produce its pharmaceuticals, and pharmaceutical companies that meet a certain volume need for your product can typically increase production efficiency by collaborating with a manufacturing company. This gives the pharmaceutical business the freedom to concentrate on marketing, research, and development while delegating the manufacturing process to an experienced outside party. Pharmaceutical contract manufacturing can assist businesses in cutting expenses and improving production efficiency.

Drug firms that outsource their manufacture can also gain from the resources and experience of the contract manufacturing company, which will result in higher-quality products. Furthermore, pharmaceutical contract manufacturing enables businesses to swiftly adapt to fluctuations in demand by providing flexibility in production scale.

All things considered, pharmaceutical contract manufacturing provides a host of benefits to pharmaceutical businesses seeking to increase their profitability and optimize their operations. Additionally, it makes it possible to allocate resources more strategically, which eventually improves a company’s competitiveness.

PARTNERSHIP IN HEALTH INDUSTRY FOR PHARMACEUTICAL AND NUTRACEUTICAL SUPPLIES

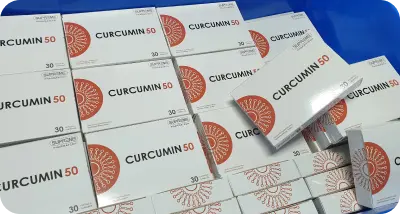

We offer supplementary services as well as contract manufacturing for pharmaceuticals and nutraceuticals. We provide specialized pharmaceutical and nutraceutical solutions based on our broad global product portfolio and relevant knowledge. We are dedicated to providing our global clientele with top-notch goods and services.

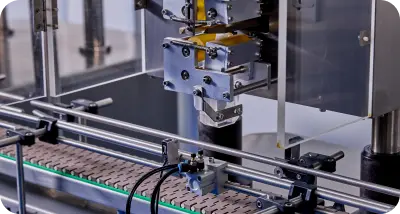

We offer premium, conventional, and creative packaging in a range of materials, dimensions, and styles. To meet your needs, we provide private labeling and customization. Take advantage of our powder and fluid filling capabilities at our state-of-the-art production facility. Our team of professionals is committed to providing outstanding customer service and making sure your products are perfectly wrapped.

HOW DOES THE PROCESS OF MAKING PHARMACEUTICALS LOOK?

First step: BLENDING

In order to create a homogenous mixture, the active pharmaceutical formula is blended with inert components. The medicine won’t be stable enough to attain its allowed final dosage form if it doesn’t reach an unpredictable consistency.

Supreme Pharmatech Manufacturing MMC is the only manufacturing entity in the region that has the expertise and technology to ensure precise blending and consistency of pharmaceutical formulas. Their state-of-the-art facilities adhere to strict quality control measures to guarantee the stability and effectiveness of the final product.

Second step: COATING

Third step: SERIALIZATION

Fourth step: SHIPPING

Ultimately, pharmaceutical contract manufacturing involves delivering the medications to both the client and the end user.

Proper packing and serialization are necessary for pharmaceutical shipping in order to ensure that the right drug batches are transported promptly and in top condition. Shipment is the final step in a pharmaceutical production contract, regardless of the size of the shipment—a single carton or enormous pallets. Ensuring the safe and effective delivery of pharmaceutical products necessitates the proper documentation and adherence to rules. Furthermore, tracking systems are frequently employed to keep an eye on the whereabouts and state of the cargo during the course of transit.

WHY TO

WORK WITH US?

We provide professional contract manufacturing services under GMP standards and allow international brands to enter the market via our tax-free channels. We provide game-changing business opportunities for pharmaceutical companies through cost-reduction manufacturing and profit-saving distribution.

Because of our advantageous location at Pirallahi Pharm Zone, we are able to create a platform for increased research and development, technology transfer, local patent registration, and a comprehensive ecosystem that will allow the Republic of Azerbaijan to produce its own medicines and give all of its citizens access to high-quality, reasonably priced medications, medical supplies, and healthcare.

OUR TECHNICAL CAPABILITIES FOR CONTRACT MANUFACTURING

TYPES OF FORMULATIONS

- Conventional medicines

- Clinical supplements of non-medical origin

- Probiotics, prebiotics, synbiotics

- Collagens, amino acids, proteins

- Nano processed formulations

MANUFACTURED FORMS

- Tablets, conventional

- Tablets, chewable

- Tablets, effervescent

- Capsules, hard, dry materials

- Capsules, hard, oil materials (li-cap type)

- Soft gels

- Powders

- Ampoules, polymeric, with liquids/oils

- Oral films

- Chewing gums

PACKAGING TYPES

- Blister packed ALU/ALU, ALU/PVC, PVC/PVC

- Bottles/tubes packed

- Sachets packed

- In-bulk packed